Origin - Jute is a natural vegetable fibre under the category of bast fibres like flax, hemp, kenaf and ramie. Since ancient times, it has been traditionally grown in the eastern part of the Indian subcontinent, which make up of the present day West Bengal of India and plains of Bangladesh. Jute is an annually renewable plant belonging to the genus Corchorus of the order Tiliacea. Normally, two species viz. Corchorus Olitorious and Corchorus capsularis, commonly known as Tossa and White jute respectively are produced in commercial scale. Another bast fibre crop commonly known as Mesta has two cultivated species – Hibiscus cannabinus and Hibiscus Sabdariffa.

The word jute was first published by Roxburg, the then Superintendent of Botanical Garden, Shibpur, West Bengal in the year 1795, in his letter addressed to the Board of Directors of East India Company. The first jute mill in India was set up in the year 1855 at Rishra, near Kolkata.

Land – Jute can grow in wide range of soil but fertile loamy alluvial soil is better suitable.

Soil pH – 6 -7.5 is ideal soil pH where jute is cultivated.

Climate – Relative humidity between 40-90% and temperature between 17° C and 41°C, along with well distributed rainfall over 1200 mm is ideal for cultivation and growth of jute.

Harvesting & Retting – Jute crop can be harvested between 100 – 120 days. After harvesting the jute bundles are kept in the field for 2 -3 days to allow leaf shedding. The bundles of jute stems after defoliation are placed in retting tank in ‘Jak’ and weighed down under water and places at a depth of 10 cm. Retting is a microbial process by which the fibre from the woody core (stick) is loosened. Bacteria and fungi act upon the soft tissues of the stem, which on dissolution makes it easy to separate the fibre from the core (stick). At normal temperature of 34° C, it taken generally 8-10 days for complete retting.

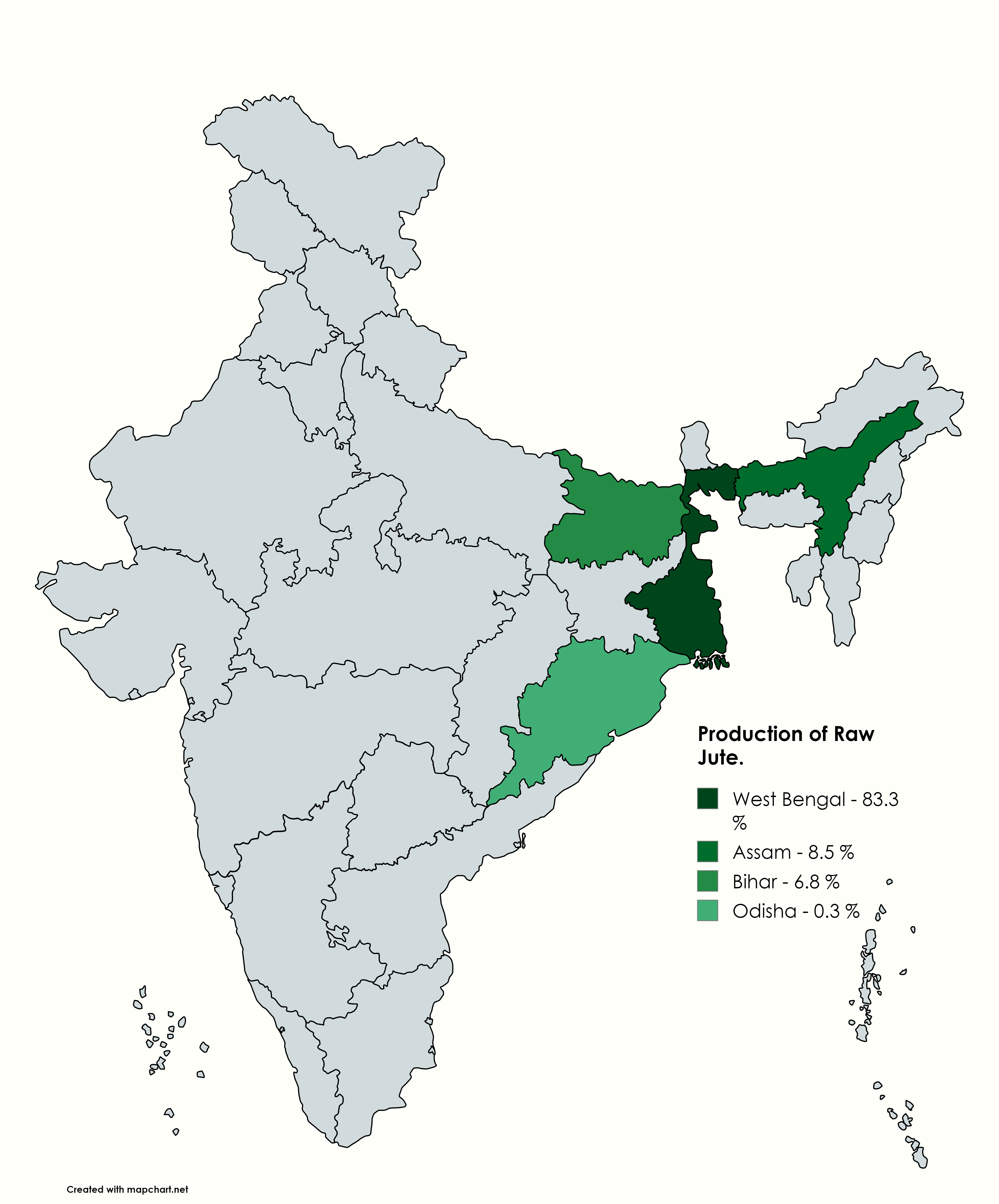

Jute Grading - Jute cultivation is confined to West Bengal, Eastern Bihar, Assam, Orissa, Tripura and Andhra Pradesh where mostly Mesta is grown. Out of these states, West Bengal, Bihar and Assam contribute about 80% of the total production. Again, these three states may be further classified quality-wise in five principal jute growing areas, i.e. South Bengal, Semi-Northern, Northern, Assam and Junglee (Purnea region). The places of origin, i.e. Mokam was the basic guiding factor in the old system of grading, whereas in the new grading system introduced by BIS in 1975, six characteristics viz. strength, defects, root content, color, fineness and bulk density have been considered for grading Tossa and White jute. The raw jute have been classified into eight grades (08), starting from TD1 / W1 (most superior) to TD8/W8 (most inferior). Mesta on the other hand has been classified into six grades (M1 to M6).

1. Selection or Batching – The word ‘selection’ means segregation of jute fibre according to quality and formulation of batch mix for different end products with reference to availability, cost and processing convenience. The selection process followed in the mill is subjective in nature.

2. Softening – In this process, the jute reeds are passed through a series of spirally fluted heavy rollers and are simultaneously subjected to an oil-water emulsion application with an objective to soften the rigid jute fibres as well as the fibre joints in the meshy jute reeds (strands of fibre) and also to clean the fibres from loosely adhered extraneous matter. Then emulsion added jute reeds are piled under a cover for 1 – 3 days, softening of the jute reeds take place due to some biological phenomenon. This process is known as ‘piling’. Softening is carried out by Softener machine or Spreader machine, the latter being more economical due to lower man-power requirement.

3. Carding – Jute carding is a critical processing stage. The breaker card is considered to be the heart of the jute processing system. The generation of spinnable fibres from long meshy jute reeds starts at this stage. This process changes the input material into sliver (tapes / ribbons) of desired linear density composed of fragments of original mesh after transverse breaking and longitudinal splitting of the jute reeds. This process is generally done in two stages, Breaker and Finisher Card, with occasional Inter Carding done in case of very coarse fibres used for sacking variety.

4. Drawing - By the process of drawing, the card slivers are made more thin with improved parallelization and thereby more suitable for spinning. Thinning (attenuation) of sliver and improvement of fibre parallelization are progressively done with the help of 2 or 3 drawing passages.

5. Spinning - In the spinning frame, the sliver delivered from the last (finisher) drawing frame is further elongated by drafting to the specified linear density of the final yarn and is finally twisted to form the yarn. Each of the jute spinning frame has 3 simultaneous and essential functions namely drafting, twisting and winding. Generally flyer spinning frames are used for spinning of jute yarn.

6. Winding - One of the main objectives of winding is to remove faulty places in the yarn like large thick places and slubs to assure better performance of the yarns during post – winding operations like weaving. Winding of warp and weft are done separately in spool winding and cop winding machine respectively.

7. Beaming - The warp yarn packages (or spools) are placed in the creel of the beaming machine which delivers the warp beam or better known as the weaver’s beam.

8. Weaving - It is basically the process of interlacement of the warp and the weft and is carried out in the loom for fabric manufacturing. The looms used in the jute industry for producing conventional products are shuttle looms, though shuttle-less looms are also used for producing finer fabrics for value added products.

9. Finishing - It consists of a sequence of steps to convert the ex-loom fabric into final sellable product. The processes along with their brief function is given below:

Steps have been taken for promoting better agronomic practices in jute farming, promotion of the Jute Diversified Products (JDPs) and their marketing, support for technological up-gradation of jute mills, promotion of JDP clusters operated by Women Self Help Groups at block level formed under National Rural Livelihood Mission (NRLM) etc. Projects for promotion of jute production and exports such as Project Jute-ICARE (Jute: Improved Cultivation and Advanced Retting Exercise),Common Facility Centre Scheme (CFCs) for supporting Women Self Help Groups (WSHGs), Incentive Scheme for Acquisition of Select Machinery (ISAPM) to increase the productivity of the jute machinery and make them efficient by replacing the old machines by new and technologically advanced machines etc. are being implemented in the jute sector.